What is metal injection molding?

Powder Injection Moulding (PIM), comprising Metal Injection Moulding (MIM) and Ceramic Injection Moulding (CIM), is an advanced manufacturing technology for the production of complex, high volume net-shape components.

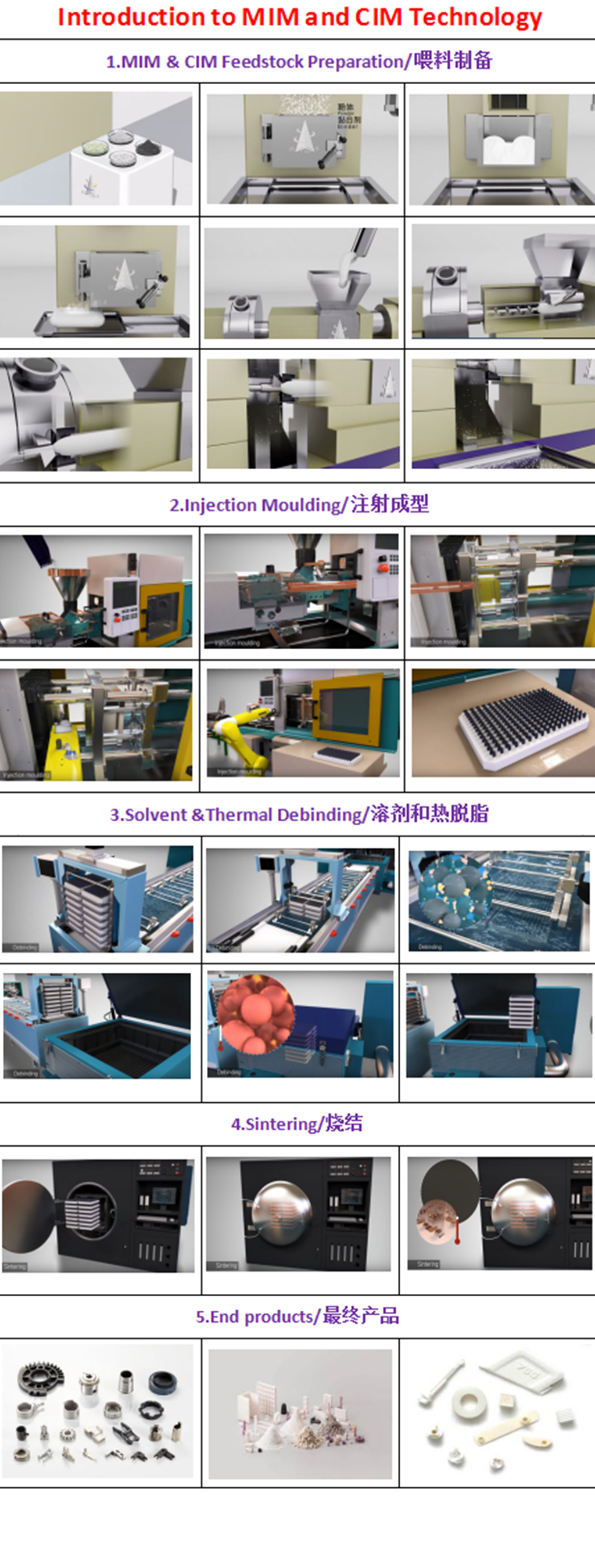

Metal injection molding (MIM) is a metalworking process in which fine metal powder is mixed with binder material to create a "feedstock" that is then shaped and solidified using injection molding. The molding process allows high volume, complex parts to be shaped in a single step. After molding, the part undergoes conditioning operations to remove the binder (debinding) and densify the powders (sintering). Finished products are small components used in many industries and applications.

Working principle:

Step 1: Feedstock – The fine metal powders are combined with thermoplastic and wax binders in a precise recipe. A proprietary compounding process creates a homogenous pelletized feedstock that can be injection molded like plastic injection molding.

Step 2: Molding – When heated, the feedstock becomes a viscous slurry which looks like melt plastic, and is injected into a mold cavity under high pressure, allowing for extremely complex shapes. Once the component is removed it is known as a "green part."

Step 3: Debinding – the “green part” is then put through a controlled process called debinding that removes most of the binders. Once the debinding is complete, the component is referred to as “brown.”

Step 4: Sintering – the “brown” part is held together by a small amount of binder and is fragile. During sintering, the temperatures reach near the melting point of the material. Sintering eliminates the remaining binder and gives the part its final density and strength. MIM products have similar properties as wrought materials.

Manufacturing process:

Metal injection molding (MIM) is a proven, innovative powder metallurgy technology that offers the capability of mass-producing complex-shaped metal parts consistently and reliably.

Metal Injection Molding (MIM) provides precision parts while eliminating extensive machining to save cost. The MIM process is ideal for firearms & defense ,medical/dental, consumer electronic parts, etc.