History of Metal Injection Molding

Metal Injection Molding (MIM) is a very recently developed process, compared to forging or casting technique.

The first studies about PIM (powder injection molding) date back to the 1920s. This idea was first developed for ceramic components, especially to CIM (ceramic injection molding). Afterward, during the Second World War, the results of these studies are applied to metal powders (Fe-Ni) and the first metal injection molded parts are manufactured.

Starting from the 1950s also in Russia has been developed a similar process, but only with ceramic powders. Since 1970 Metal Injection Molding (MIM) found in the United States more and more applications in those fields where complex-shaped and high properties components are required. MIM became an industrial process, and the process spreads rapidly in Japan, and finally in Europe, Russia, and China too.

MIM industry shows explosive growth in the past 8 years (2011 to 2018), including market applications, products, MIM equipment, MIM parts manufacturers, as well as the MIM parts processing plant, which promotes strong vitality to the industry.

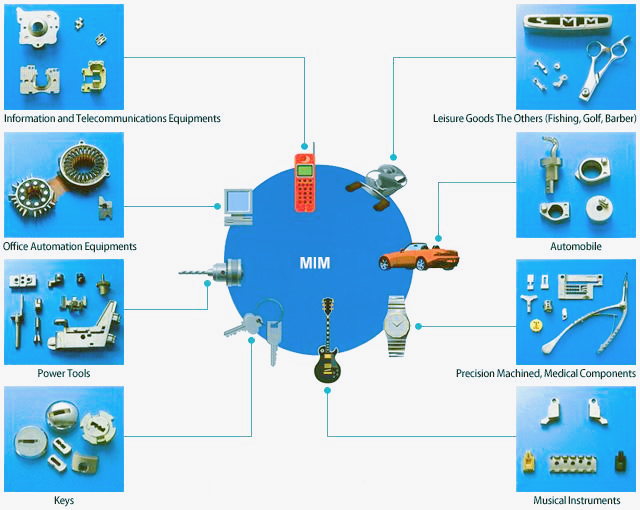

The metal injection molding market is projected USD 3.77 Billion by 2022. The growth of this market can be attributed to the increasing demand for small and complex metal injection molded parts from end-use industries, such as electrical & electronics, automotive, medical & orthodontics, industrial, consumer products, and firearms & defense.

New product launches and expansions were the major developmental strategies adopted by key players operating in the metal injection molding market. Companies such as Indo-MIM (India), Dynacast International (US), ARC Group Worldwide (US), Smith Metal Products (US), and NetShape Technologies (US) adopted these strategies to enhance their product offerings and customer base as well as to gain a competitive edge over their peers in the market. These companies are also focused on investing in research & development activities to introduce new and cost-effective materials to keep up with the changing consumer needs.