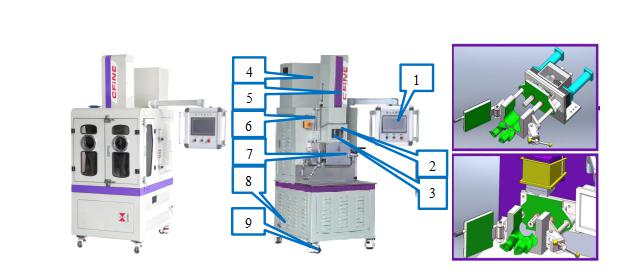

Main pictures:

1:Operation panel 2:Dust cover 3:Pressing ram 4:Electric control box 5:Cylinder 6:Interlock switch 7:Mixing chamber 8:Cooling water inlet and outlet. 9:Caster

Applications

The atmosphere protection mixer is mainly used for: lithium battery powder, titanium alloy powder, tungsten carbide powder, nickel-based alloy and other materials that need to be insulated from oxygen when compounding with binders. Reduce the impact of oxygen in the mixing process. Maximize the reduction of oxygen content. The content of the oxygen is below 1000ppm when the machine is working.

Equipment advantages

(1) It only takes approx 1 hours for metal powder every batch .Also you can shorten or lengthen the mixing time to get a better dispersing result .Compared to the previous processing methods ,it is more efficient.

Shorter time ,and don’t need to crush for mixing second time. Reduce the pollution in the process of crushing.

(2) The whole mixing chamber can be totally opened and the rotors also can be taken off which makes it easier to clean.No materials residue.

When running trials using this machine, you don’t need to worry about the cross-contamination between different formulations.Ensure the accuracy of the experimental data.

(3) Spraying special wear-resistant material imported from German(the green color in the picture above);

After surface treatment, the equipment has sufficient hardness to process different materials. The service life of equipment is improved. Also reduce the pollution during processing.

(4) Heated and cooled by electrical bar and water channel in the side wall of mixing chamber.

The temperature probe is at the bottom of the mixing chamber, and the temperature of the material is accurately measured. Temperature heating and cooling are faster than conventional equipment.

(5) Equipped with PLC and the speed of the rotors is adjustable . Avoid powder flying in the early stage .

(6) When the inert gas is filled ,the oxygen content is bellow 1000 ppm. The oxygen content fluctuates little during the entire mixing process.Effectively prevents the material from being oxidized.

Main device parameters

Output:Approximate 20-23kg/h for MIM(Depending on the material)

NO. | Description | Parameter | Brand name |

1 | Working volume | 5 | CFine |

2 | Weight per batch | 20-23kg |

|

3 | Main motor | 11KW | TECO |

4 | Reducer | Hardened surface reducer | Guomao |

5 | Cylinder | ¢110 | AirTAC |

6 | Bearing | NSK | NSK |

7 | Speed(L/R) | 0-40/31 r/min |

|

8 | Temperature range | Room temperature to 300℃ |

|

9 | Heating method | Electrical bar |

|

10 | PLC |

| FATEK |

11 | Low-voltage electrical components/ |

| Shihlin,Omron,Tiande,Fotek etc. |

12 | Weight | 2530kg |

|

13 | Dimension | L1200*W1300*H2350mm |

|

14 | Power | As required |