Main picture

Applications:

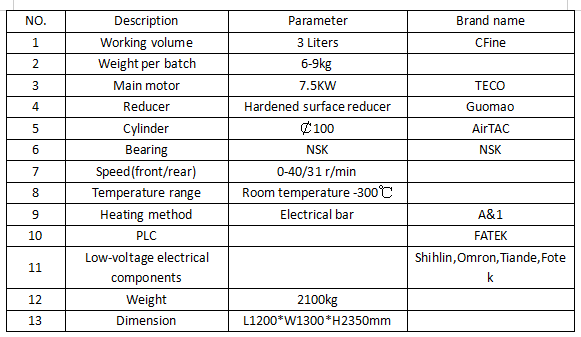

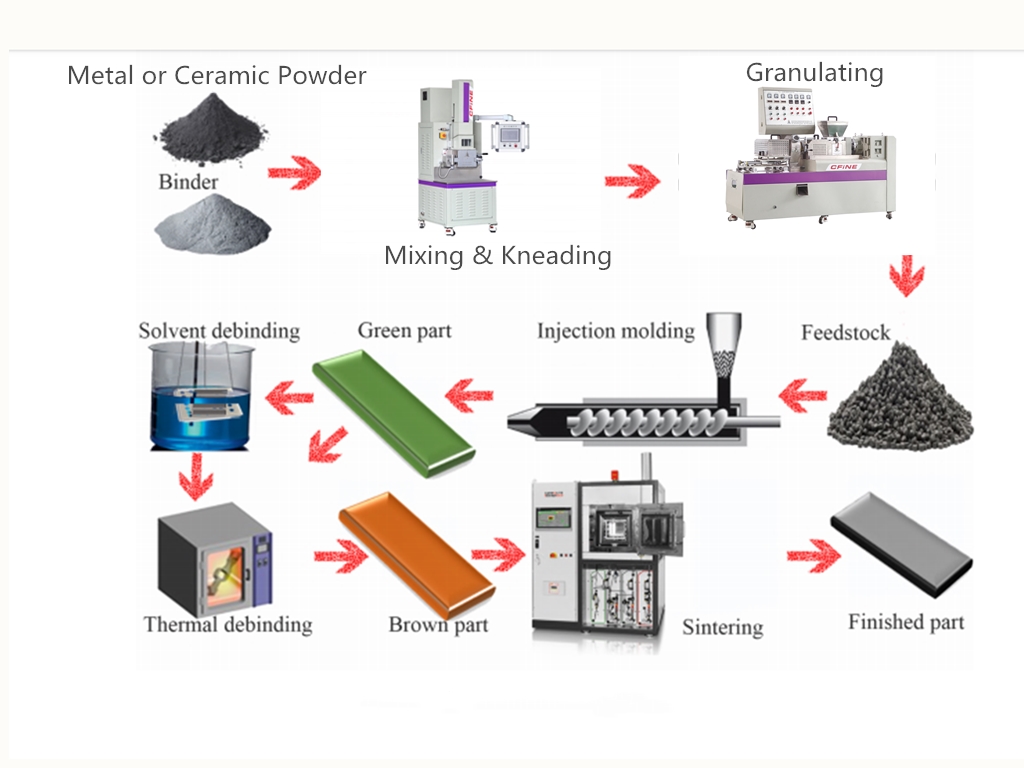

Ceramic kneader is specially designed for mixing ceramic powders and binders .Such as alumina, zirconia, silicon nitride, boron nitride, silicon carbide etc. Usually the ceramic kneader is used in ceramic injection molding (CIM) industry.

The ceramic kneader also can be used in metal injection molding and plastic injection molding process .

Advantages:

(1) It only takes approx 3 hours for every batch .Also you can shorten or lengthen the mixing time to get a better dispersing result .Compared to the previous processing methods ,our ceramic kneader is more efficient.

Shorter time ,and don’t need to crush for mixing second time. Reduce the pollution in the process of crushing.

(2) The whole mixing chamber of our ceramic kneader can be totally opened and rotors also can be taken off which makes the ceramic kneader easier to clean.No materials residue.

When running trials using this machine, you don’t need to worry about the cross-contamination between different formulations.Ensure the accuracy of the experimental data.

(3) There are three kinds of surface treatments for the mixing chamber (parts connecting with the materials) for different requirements.

1) Hard Chrome-plating;

2) Spraying tungsten carbide imported from Germany(the green color in the picture above);

3) A specially alloy steel imported from Japan(the whole mixing chamber,rotors and ram are made of this alloy).

After surface treatment, the equipment has sufficient hardness to process different materials. The service life of our ceramic kneader is improved,1-2 times longer. Also reduce the pollution during processing.

(4) Ceramic kneader is heated and cooled by electrical bar and water channel in the side wall of mixing chamber.

The temperature probe is at the bottom of the mixing chamber, and the temperature of the material is accurately measured. Temperature heating and cooling are faster than conventional equipment.

(5) Our ceramic kneader is equipped with PLC and the speed of the rotors is adjustable . Avoid powder flying in the early stage .